PRODUCT

About the Scribing and Breaking Processes

The process of seperating the numerous integrated circuits developed on semiconductor wafers into individual dies (dice) or chips is done via a process referred to as wafer dicing, die singulation, or other similar terminology.

Common methods of die singulation involve the use of dicing saws which use a rotating blade to cut through the wafer, or high intensity lasers (laser ablation) to melt or burn away the area between the dies often called 'streets'.

Another method of separating the dies is via the Scribe and Break method.

At Kumasan Medix, we produce Scribing and Breaking Machines to separate the wafers via the methods described below.

What is Scribing?

-

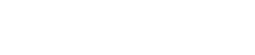

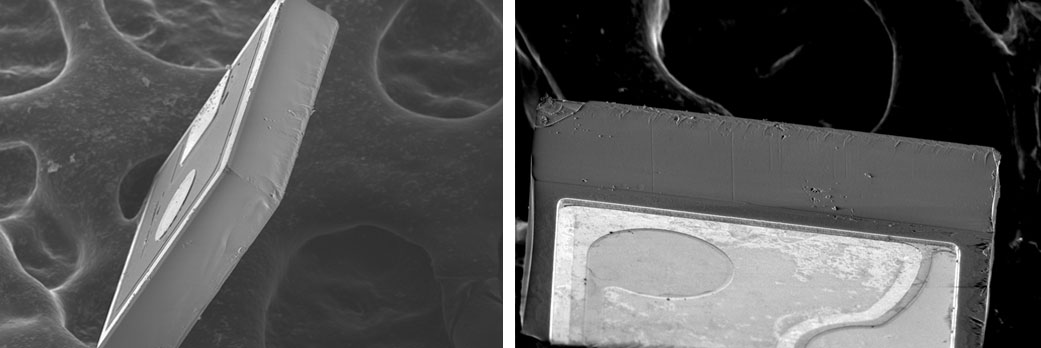

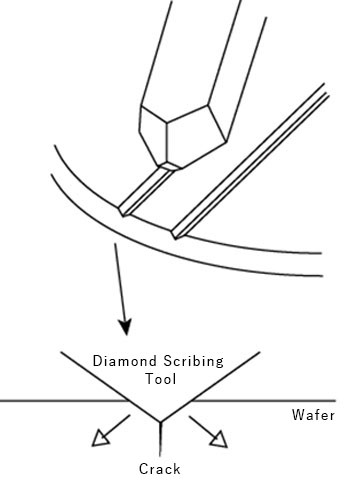

Scribing describes the use of a diamond scribing tool or laser in order to create a groove on the surface of the wafer, from which a crack is spawned. In the following breaking process, pressure is then applied to the other side of the wafer in order to expand that crack and 'break' the wafer into individual chips.

Our Scribing Machine uses a diamond scribing tool birthed from years of accumulated engineering to scribe the wafer which, after breaking, creates a smooth, mirror-like cut face of the die.The benefits of diamond scribing

・No heat: The cut surface of the die is undistorted by the heat that would be generated via laser or the friction of a dicing saw.

・Dry process: There is no need for water to clean or cool the wafer. Scribing can be used on materials that dislike water. There is no need to use the factory's water facilities, allowing for more freedom in the installation's location.

・No dicing stress: Only a small amount of pressure is applied to the wafer, minimizing wafer stress. This is perfect for harder materials which may encounter severe chipping if processed via dicing saw.

・Zero cutting width: Shortening the street width frees up space for more chips to be obtained from a single wafer.

・Smooth, clean cut surface: the side faces of the chips would have no heat damage that would result from lasers, or chipping from dicing saws. This is perfect to maximize the intensity of LED chips.

Other names: Scribe machine, Scriber, Wafer Scribing Machine, Wafer Scriber

What is Breaking?

-

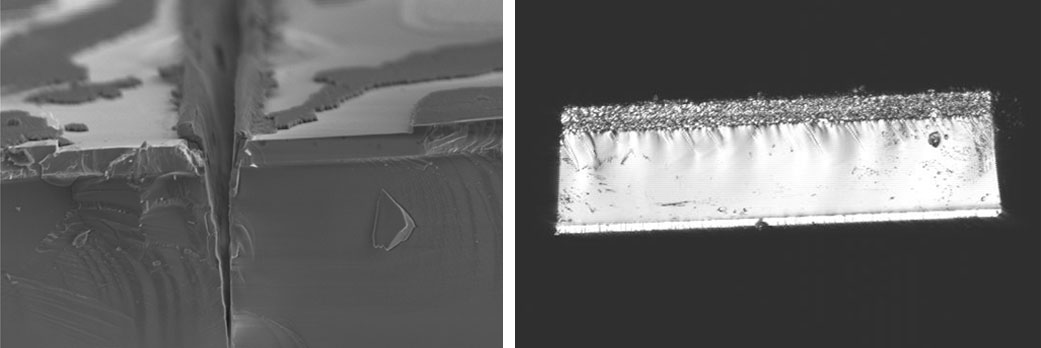

Wafer breaking is the act of applying pressure to the underside of a scribe line in order to propagate (enlarge) the crack created in the scribing process until the wafer is broken into two pieces.

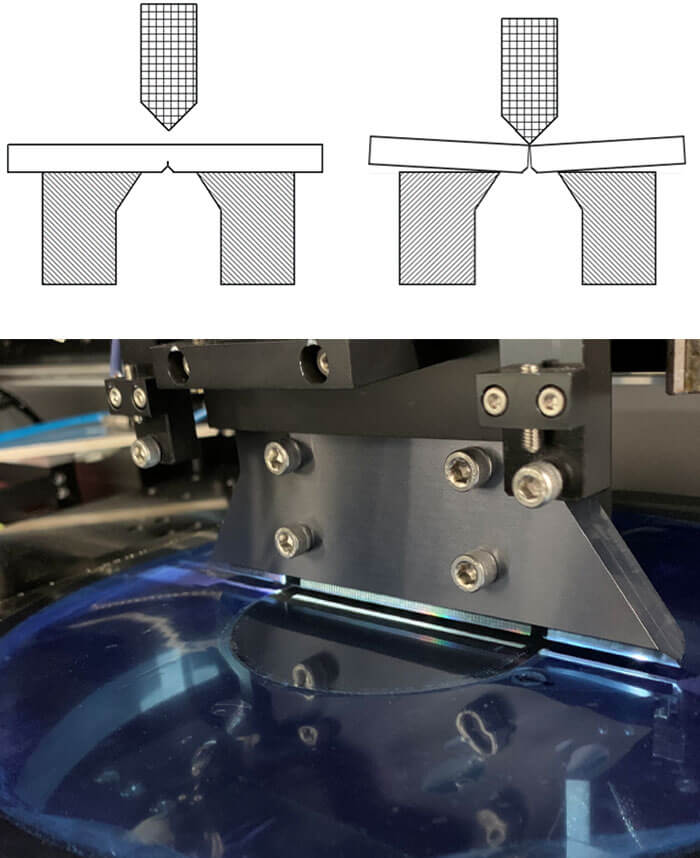

There are multiple methods to breaking a wafer, however our Breaking Machine employs the guillotine method as seen in the image to the right.

Typically, protective film is placed over the scribed surface and the wafer is placed scribe line facing down onto a 'table' which opens up in the middle. Then, a blade decends from above to enlargen the crack and separate the wafer.The benefits of breaking

・Versatility: Breaking can be used in combination with a number of scribing processes such as Diamond Scribing, Laser, Half-Cuts, Stealth, etc.

・Reduced street width: as breaking is simply the propagation of cracks, it does not require a large cutting width. This leads to the potential ability to increase the chips per wafer ratio.

・For hard or brittle substrates: Breaking is particularly effective on hard materials such as compound semiconductors which may encounter chipping or other large damage when processed via dicing saw.

Other names: Breaker, Breaker Machine, Wafer Breaker, Wafer Breaking Machine